HW-FZ Магнитный порошковый тормозной тормозной вал Тип 26.05.05.05.050/100/200 Н.М. Для расписания

>= 1 Часть

US $80.00 ~ 400.00

Самые продаваемые

- Обзор

- ТЕХНИЧЕСКИЕ ХАРАКТЕРИСТИКИ

- ДРУГИЕ

The magnetic powder clutch is composed of the active rotor (input shaft), driven rotor(output shaft)

and yoke with excitation coil. The three parts are assembled relative concentric and form a system that can rotate relatively. The annular gap between the active rotor and the driven rotor is full of magnetic alloy powder which has high magnetic conductivity.

The magnetic powder will be in the state of the loose situation when the current does not pass the excitation coil, the magnetic powder will be thrown on the inner wall of the active rotor, in this case, there will not exist the interaction force between the active and driven rotor. So the magnetic powder clutch is in the state of separation, with no torque transmission exits.

The magnetic powder in the working chamber will link in a link-state under the action of the magnetic flux generated from the yoke when the current passes the excitation coil. The magnetic powder clutch can transfer torque relying on the shear force generated from the magnetic chain and the friction generated from the magnetic powder and working face. In this situation, the magnetic powder clutch is in the combination state.

When the current is cut off, the magnetic flux will disappear along with the disappearance of the magnetizing current, the magnetic powder will be in the state of loose under the action of gravity again, and will be thrown on the inner wall of the active rotor under the action of the centrifugal force.

In this case, the magnetic powder clutch will be in a state of separation again.

The magnetic powder clutch and brake have the same principle, the magnetic powder brake will form as long as the driven rotor of the magnetic powder clutch is fixed.

Technical parameter:

| Model | MAIN TECHNICAL PARAMETER | DIMENSION SIZE | N.W | |||||||||||

| Torque | Voltage | Rotational speed | Max Current (A) | D1 | D2 | D3 | L2 | L1 | L3 | 6-s | d | t | kg | |

| FZ6K-3 | 6 | 24 | 1000 | 0.8 | 130 | 62 | 52 | 57 | 3 | 60 | M4 | 16 | 5 | 3 |

| FZ12K-3 | 12 | 1 | 150 | 82 | 65 | 67 | 3 | 70 | M5 | 20 | 6 | 4.5 | ||

| FZ25K-3 | 25 | 1.5 | 182 | 110 | 90 | 74 | 4 | 78 | M6 | 25 | 8 | 7.5 | ||

| FZ50K-3 | 50 | 1.8 | 219 | 130 | 110 | 91 | 5 | 96 | M8 | 30 | 8 | 12 | ||

| FZ100K-3 | 100 | 800 | 2 | 260 | 140 | 120 | 105 | 5 | 110 | M10 | 35 | 10 | 20.5 | |

Features

The magnetizing current has a linear relationship with torque

The transmission torque has a linear relationship with the magnetizing current. The size of the torque can get controlled within a larger range. Under normal circumstances, the magnetizing current

Has a linear relationship with transitive torque within the range of 5%-100% rated torque.

Stable slip torque

The slip rotational speed between the driven rotor and active rotor does not affect the transitive torque when the magnetizing current remains unchanged, as shown in chart 4. That is to say, the static friction torque and the dynamic friction torque have no difference. Therefore, the torque can retain constant stably. The features are applied to tension control, users can control the tension of the roll material effectively as long as adjustment the magnetizing current accurately.

Prevention heat phenomenon from slip

The friction part will generate heat inevitably or even be destroyed when it keeps continuously sliding.

But this device has a complete cooling set, it will not generate a lot of heat after a long time running and it has a long service life.

Application

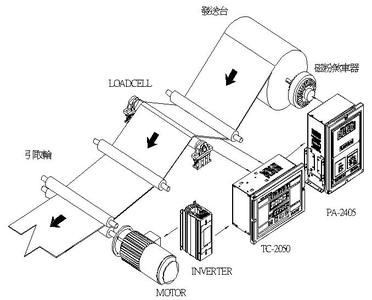

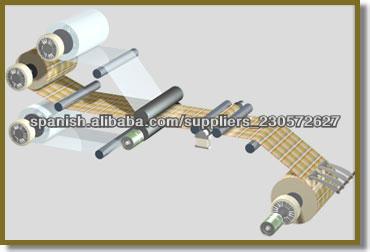

Due to the features of the magnetic powder clutch and brake, they have been widely used in papermaking, printing, plastic items, rubber industry, textile industry and dyeing, wire and cable, metallurgy industry, and tension control of winding and unwinding in roll material processing industry. A complete set of schematic of the tension control system is as follows:

Notes

Don’t overload, meanwhile cool to the appropriate temperature

The value of the torque/rotational speed/slip power should be less than the rated value, The cooling model(natural cooling. forced air cooling/water cooling)should depend on the maximum slip power when it works and the cooling air should filter the water and oil. The temperature detector and the alarm device should be installed to prevent high temperatures which can affect the service life of the magnetic powder. (the highest temperature is 80 degrees)

The life of the magnetic powder clutch and brake rely on the life of the magnetic powder. Generally speaking, its service life is 4500-7500 hours in the state of non-overloaded, but its service life can extend several times in some cases, such as the working torque of the magnetic powder clutch/brake, relative slip rotational speed and slip power can be reduced to 50%-70% of the rated value. This is to say, the margin can be enlarged as soon as possible when designing.

Concerning the torque

After the magnetic powder clutch and brake working, the magnetic powder will be in grinding at the beginning which lead to the torque decreasing slightly, but the gap can be compensated through adjustment the current.

Больше вариантов

English

English العربية

العربية français, langue française

français, langue française हिन्दी, हिंदी

हिन्दी, हिंदी Bahasa Indonesia

Bahasa Indonesia فارسی

فارسی Português

Português Español

Español Afrikaans

Afrikaans