HW-CS Capacitivo anti-choque estático eliminador óleo imerso tipo para neutralização eletrostática industrial

>= 1 Unidade

US $50.00 ~ 80.00

Mais vendido

- VISÃO GLOBAL

- ESPECIFICAÇÕES

- DE OUTROS

Static electricity is a problem that companies face globally. It primarily affects industries, which handle non-conductive materials like plastics, paper, board, laminates, and textiles. The electrostatic attraction-repulsion causes materials to stick to machinery, or to each other, leading to jams, slow machine speed, and poor quality and productivity. Friction, pressure, and separation are the major causes of static electricity. When humidity is lower, higher static charges are generated. It becomes more noticeable in the months of winter, in dry laminates, and in air-conditioned environments.

We have designed the 683 series Static eliminator power supply and the different discharge bars for active discharging of disruptive static charges, which develop during the production processes. The discharge bars and the power supply are used primarily in cases where disruptive static charges on fast-moving material webs impair production processes and are required to be eliminated.

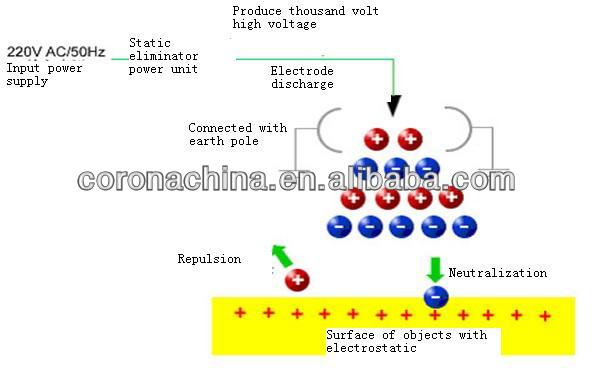

Working Principle

When the machine is underworking, the discharge around the needle generates substantial positive and negative ions, then any object with electrostatic pass through the ions zone, the neutralization happened, in other words, the electrostatic is neutralized. The static is eliminated in this way.

Features & Benefit

- Consistent, uniform winding gives a more robust and stable performance.

- More powerful static neutralization, lower electrical stress, and increased reliability.

- Imported capacitor with good pressure-resistant and temperature-resistant.

- Easy installation.

- Adopt oil immersed-type high voltage transformer, which overcomes the easy short circuit and sparking of epoxy resin casting high voltage transformer.

Technical Parameters

Model | 15KV | 16KV | 18KV |

Input Voltage | AC220V | AC220V | AC220V |

Output Voltage | 15KV | 16KV | 18KV |

Rated Power | 200W | 250W | 280W |

Output Mode | Direct Type Capacitance Type | Direct Type Capacitance Type | Direct Type Capacitance Type |

Cover Material | Plastic | Iron | Iron |

Working Way | 24h continuation | 24h continuation | 24h continuation |

Dimensions | 205*130*140mm | 250*155*165mm | 250*155*165mm |

Net Weight | 3.0KGS | 5.0KGS | 5.2KGS |

Applications | Packaging Plastics Printing Paper Food Pharmaceutical Electronics Textiles Optics | ||

Working Principle Graphic

More details pictures

Mais escolhas

English

English العربية

العربية français, langue française

français, langue française हिन्दी, हिंदी

हिन्दी, हिंदी Bahasa Indonesia

Bahasa Indonesia فارسی

فارسی русский

русский Español

Español Afrikaans

Afrikaans